Frame and hardware is die casted by digitally automatic casting machines including CNC processing and so on, to achieve better details and polished surface. Frame is welded by automatic machines to present more precise and stronger welding

We use the automatic injection machines for the plastic parts

We use multiple auto-coating lines for painting surface which presents perfect coating appearance and efficient painting capacity.

We set efficient assembly line for different processes and models to work efficiently and avoid mistakes.

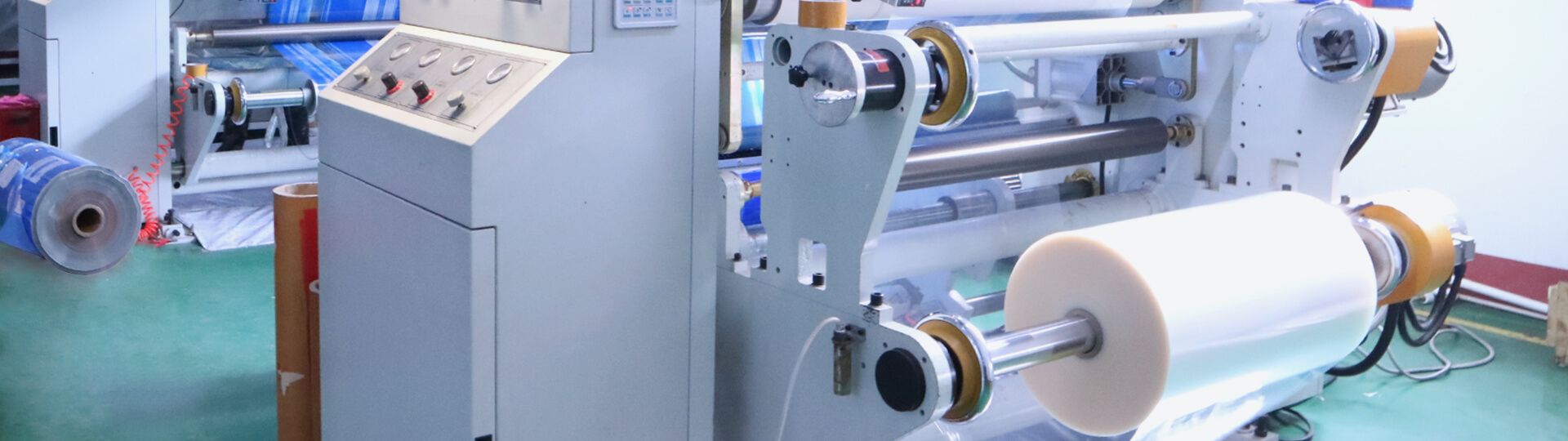

We use auto-packing machine to present efficient and neat packing appearance.

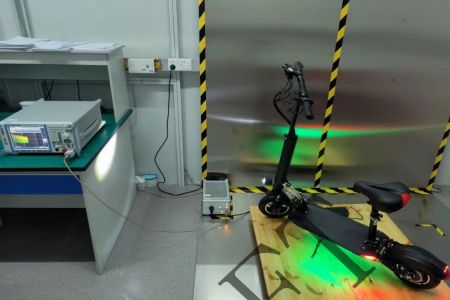

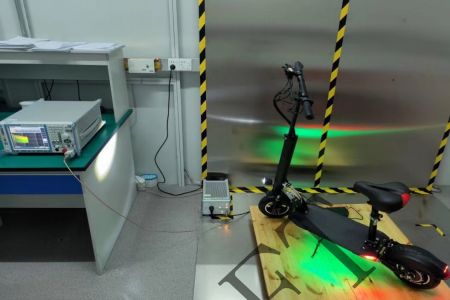

To test battery capacity and charger performance stability

To test all data performance of controller

QC for incoming materials and parts before production

QC for production process to ensure all requests and data are correct as orders

QC for all assembled vehicles to check all data and performance

QC for all assembled vehicles including stickers, size, apperance, packing, and so on

QC to ensure everything is correct before it comes to customers

We will contact you within 24 hours.